Frame-and-Fill Protection

Successful Chip-on-Board manufacturing relies on securely protected wire bonded connections. There are several options for this protection that include conformal coating, glob top, and frame and fill (also commonly referred to as dam and fill). Each offers its own advantages, but the frame and fill method provides the highest level of protection with processing consistency. Benefits include:

- Superior moisture/environmental resistance

- Increased mechanical strength to the PCB

- Ability to maintain specific coverage dimensions and weight

- High voltage isolation

- Fragile component stability

- Mechanical shock resistance

- Security of thick, opaque protective layer

- Cosmetic appeal- molded appearance

- No material migration under surrounding components

- Low viscosity fill material eliminates voids under wires

- Small particle size filler to permit flow through fine wire gaps

- High Tg materials for minimal movement

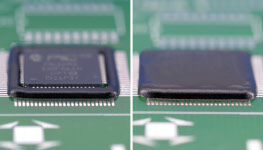

A stable "frame" is filled with low-viscosity fill material and results in a homogeneous protective coating of sensitive components

Download brochure:

For optimal processing speed, the Structalit® series of frame and fill epoxies from Panacol can be dispensed wet-on-wet. The higher viscosity frame, and the lower viscosity fill materials have been formulated to form a single, homogeneous protective coating when fully cured. These Structalit® epoxies are black in color and cure quickly with heat. They are scratch and chemical resistant, do not bleed, and have high glass transition temperatures (Tg) for minimal movement.

Also available for frame and fill are a selection of Vitralit® UV curable epoxies from Panacol. The Vitralit® epoxies are translucent materials and can be cured with UV light. This permits very fast, in-line curing cycles, which increases production throughput. The low temperatures of UV curing are ideally suited for use with temperature-sensitive PCB components. These UV epoxies also contain thermal cure catalysts, that facilitate curing in areas shadowed from UV light, and areas where the applied epoxy layer is particularly thick. With the exception of translucency, the physical properties of the Vitralit UV epoxies are similar to the Structalit® epoxies. Both possess low ion content, (less than 20ppm), which makes them suitable for microelectronics packaging.

The following tables identify Panacol’s selection of frame and fill adhesives. Additional products are also available for complete PCB assembly solutions. If standard products do not fully meet required performance, Panacol-USA can provide customized adhesive options. Technical Data Sheets (TDS) can be downloaded by clicking on the adhesive name below.

Frame-and-Fill adhesives for semiconductor applications (< 20 ppm)

| Adhesive | Application | Viscosity [mPas] | Base | Curing | Properties |

|---|---|---|---|---|---|

| Structalit® 5704 | Frame-material for Frame&Fill | 60,000-100,000 (Rheometer, 25 °C, 10s^-1) | epoxy | thermal |

black color stable frame suitable in combination with Structalit 5717-5721 no bleeding very low ion content (<10ppm) high glass transition temperature |

| Structalit® 5717 | Fill-material for Frame&Fill | 3,000-8,000 (Rheometer, 25°C, 10s^-1) | epoxy | thermal |

Black color, very good flowability High glass transition temperature No bleeding Very low ionic content (<10ppm) Suitable for semiconductors |

| Structalit® 5719 | Fill-material for Frame&Fill | 7,000-11,000 (Rheometer, 25°C, 5s^-1) | epoxy | thermal |

Very good flowability High glass transition temperature No bleeding Very low ionic content (<10ppm) Suitable for semiconductors |

| Structalit® 5720 | Fill-material for Frame&Fill | 10,000-15,000 (Rheometer, 25°C, 5s^-1) | epoxy | thermal |

Very good flowability High glass transition temperature No bleeding Very low ionic content (<10ppm) suitable for semiconductors |

Frame-and-Fill adhesives for electronics applications (< 900 ppm)

| Adhesive | Application | Viscosity [mPas] | Base | Curing | Properties |

|---|---|---|---|---|---|

| Structalit® 5891 T | Frame-material for frame&fill | 80,000-150,000 (Rheometer, 25 °C, 10s^-1 ) | epoxy | thermal |

Black color stable frame material, can be applied wet-in-wet with filling material, suitable for frame stacking stable edges resistant to shocks |

| Structalit® 5791 | Frame-material for "Frame&Fill" | 45,000-65,000 | epoxy | thermal |

black color excellent shock resistance low halogen content <900 ppm |

| Structalit® 5893 | Fill material for frame&fill | 6,000-10,000 (Rheometer, 25°C, 10s^-1) | epoxy | thermal |

Black color excellent flow properties filling material for frame&fill applications high resistance to heat and chemicals certified to ISO 10993-5 standards |

| Structalit® 5894 M |

Glob top encapsulation Encapsulation of electronic components Bonding of electronic components Fill material for frame&fill |

20,000-30,000 (Rheometer, 25 °C, 20s ^-1) | epoxy | thermal |

Black color excellent flow properties filling material for frame and fill applications on PCBs, very high resistance to heat and chemicals |

UV-curable Frame-and-Fill adhesives (< 20 ppm)

| Adhesive | Application | Viscosity [mPas] | Base | Curing* | Properties |

|---|---|---|---|---|---|

| Vitralit® 1671 | Frame material for frame & fill applications | 9,000-14,000 (Rheometer, 10s^-1) | epoxy |

UV secondary heat cure |

Stable frame compound high ion purity electronic grade adhesive high temperature conductivity low water absorption UL94 HB test passed |

| Vitralit® 1650 | Fill for frame&fill | 3,000-5,000 | epoxy | UV |

Electronic grade low ion content suitable for chip protection UL94 HB test passed |

| Vitralit® 1680 | Fill for frame&fill | 5,000-8,000 | epoxy | UV |

Very high resistance to heat and humidity electronic grade adhesive low ion content suitable for chip protection |

| Vitralit® 1691 | Fill for frame&fill | 20,000-40,000 | epoxy |

UV secondary heat cure |

black color high ion purity electronic grade adhesive high temperature resistance fast surface curing with UV light |

*UV = 320 - 390 nm