Epoxy adhesives

Epoxy resin-based adhesives continue to evolve and improve. New single and two-component epoxy introductions are stronger, faster curing, and easier to work with. Epoxies exhibit minimal shrinkage and offer superior chemical and environmental resistance. Epoxy adhesives can be either cured at room-temperature (two-component), thermally or using UV or visible light.

Panacol epoxies are packaged under the brand names of Structalit®, Elecolit® and Vitralit®.

Structalit® epoxy adhesives

Structalit® epoxies are high performance adhesives, delivering superior strength, thermal stability, and chemical resistance. The epoxies form incredibly high strength structural bonds that are demanded in panel assembly, frame attachment, and ferrite bonding. In addition, selected products are ideal for sealing and encapsulating (glob top) electronic and electrical components such as smart cards. They are also ideal for potting and casting applications. Structalit® products are available as single component or two component systems. The single component adhesives offer easy dispensing and fast, thermal curing. Two-component epoxy systems can be cured at room temperature or accelerated with heat. Various pot-life schedules are available to accommodate the infinite number of global production processes.

Beige epoxy adhesive resistant to oils and fuels is used in the automotive and aerospace industry

Elecolit® epoxy adhesives

Elecolit® epoxies combine thermal and electrical conductivity with excellent bond strength. The electrically conductive epoxies are ideal for antenna printing, die bonding, and other electronic assembly associated with PCB, FPC, and LCD production. The thermally conductive epoxies facilitate heat transfer and are typically used to affix heat sinks and power modules.

Vitralit® epoxy adhesives

Vitralit® adhesives are Panacol’s product line of innovative light curable epoxies based on cationic cure. Unlike light curable adhesives that utilize free radicals to initiate the polymerization process, light curable cationic cure epoxies absorb light energy to generate ions that initiate an ionic polymerization process. This translates to the following advantages:

- Light curable cationic epoxies are not subject to oxygen inhibition, which means the cured adhesive surface is dry and tack-free

- Light curable cationic epoxies have little or no shrinkage during cure

- Light curable cationic epoxies are low in odor

- Light curable cationic epoxies are abrasion and chemical resistant

In the event that exposure to UV light curing energy is terminated prior to the light curable cationic epoxy becoming fully cured, it will continue its polymerization without light energy (in the previously illuminated area) until full cure is achieved (also referred to as “delay cure”).

Light curable cationic epoxies combine proven epoxy durability with the processing speed of today’s light curable adhesives. Epoxy bonds possessing high strength, extreme clarity, and moisture resistance can be developed in seconds using a UV/Visible light curing process. These products are ideally suited for applications that are subject to environmental stresses, higher operating temperatures, and extreme wear.

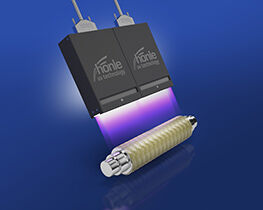

LED curable cationic epoxies are available. These new formulations can be cured with LED curing systems at 365nm wavelength. Matching curing equipment is available from our partner, UV equipment manufacturer Honle.

UV curable epoxies can be used for filament windings

UV curing equipment:

UV system solutions with Panacol uv curable epoxy adhesives and innovative curing systems from Honle

Tpyical applications for epoxy-resin based adhesives include: